Featured Projects

Here are a few of the projects we've been talking about lately.

Portfolio Overview

Over our 45-year history, VAA has completed thousands of projects in a broad range of industries and geographic locations. Explore a few of the unique solutions we've developed to address client challenges.

All Projects

- All Projects

- Master Planning

- Port and River Terminal Design

- Civil Engineering

- Rail Design

- General Arrangement

- Process Engineering

- Industrial Architecture

- Structural Engineering

- Mechanical Engineering

- Electrical Engineering

- Origination

- Processing

- Manufacturing

- Consumer & Service

- Distribution

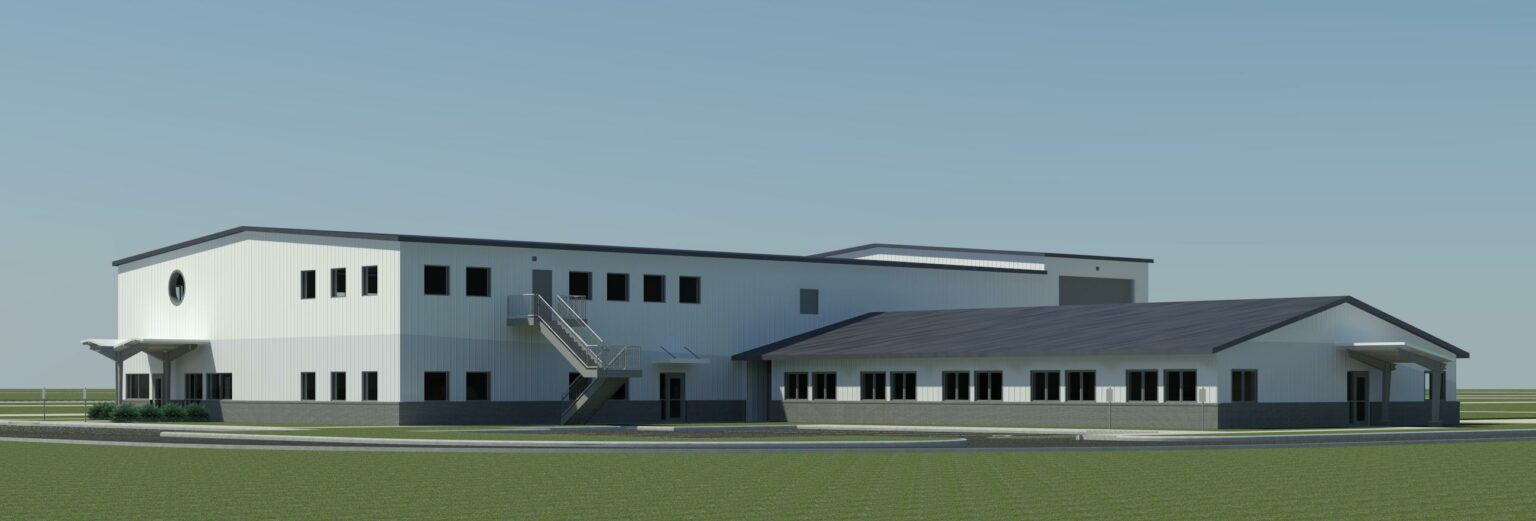

Cooperative Farmers Elevator Feed Mill

VAA provided structural engineering and industrial architecture services for CFE’s new 780,000 tons/year feed mill, now one of the largest feed mills in the state.

Malt Production Facilities

VAA’s multidisciplinary team provided designs and facility layout for the expansion of two facilities, each now capable of producing 25,000 metric tons of malt per year.

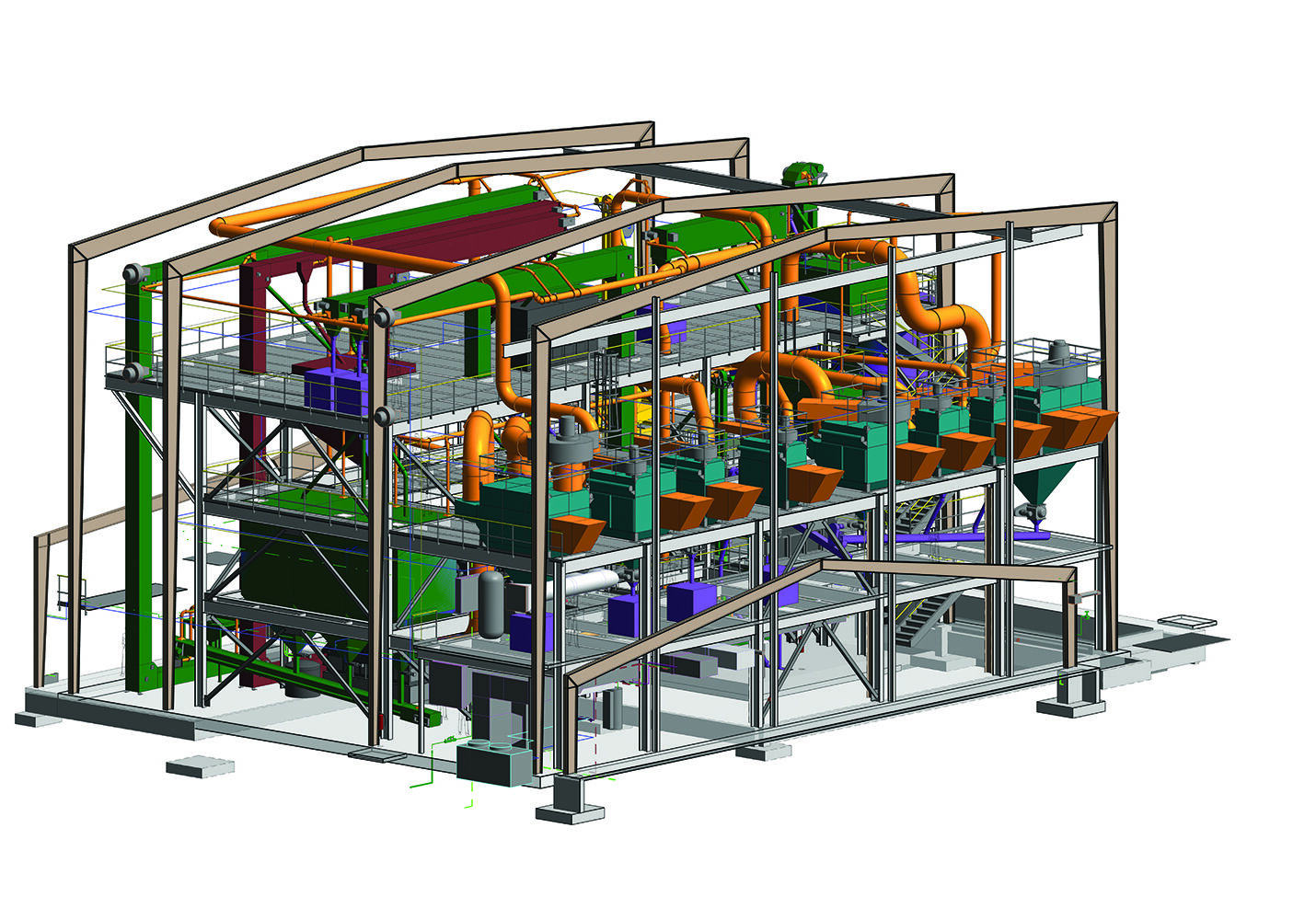

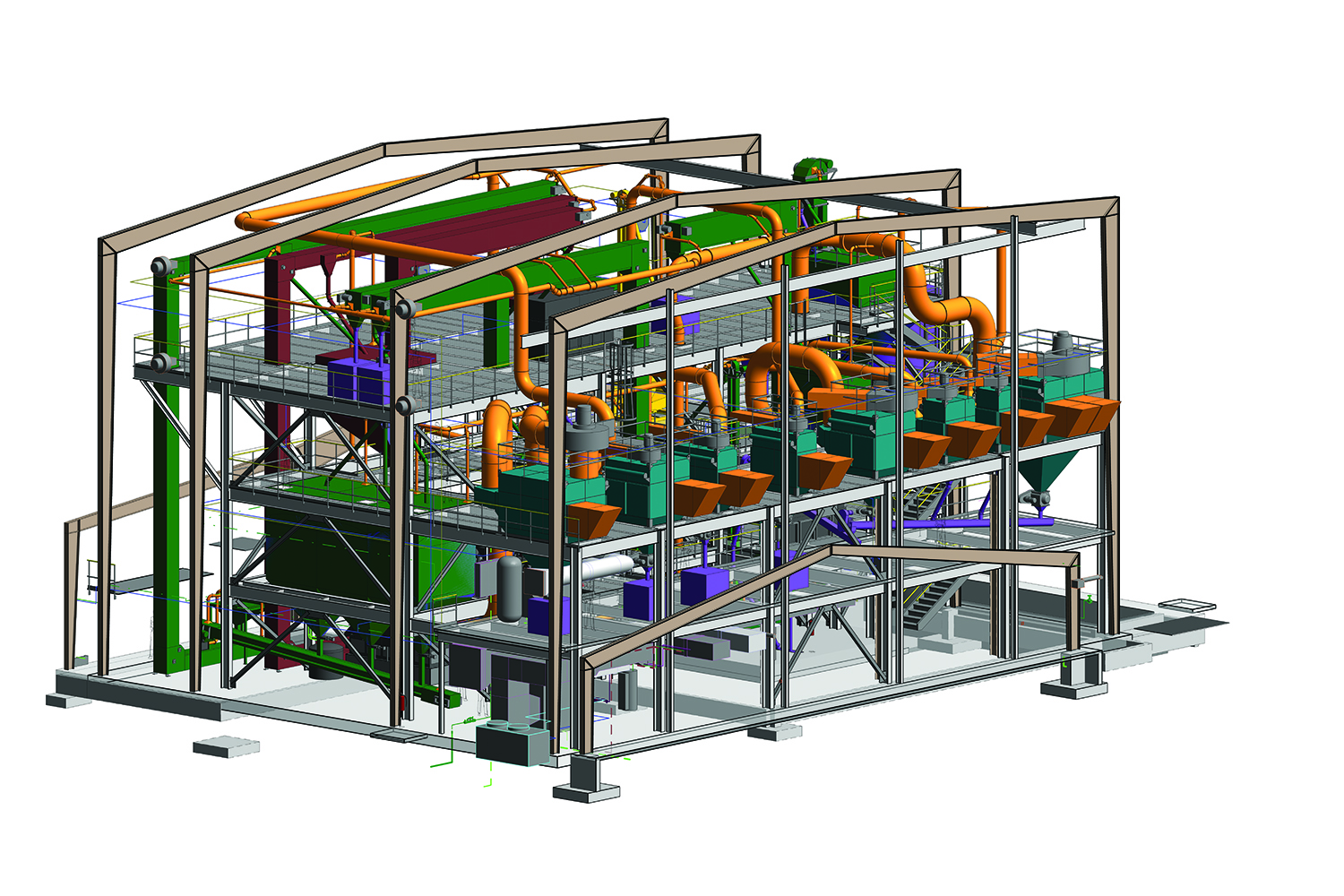

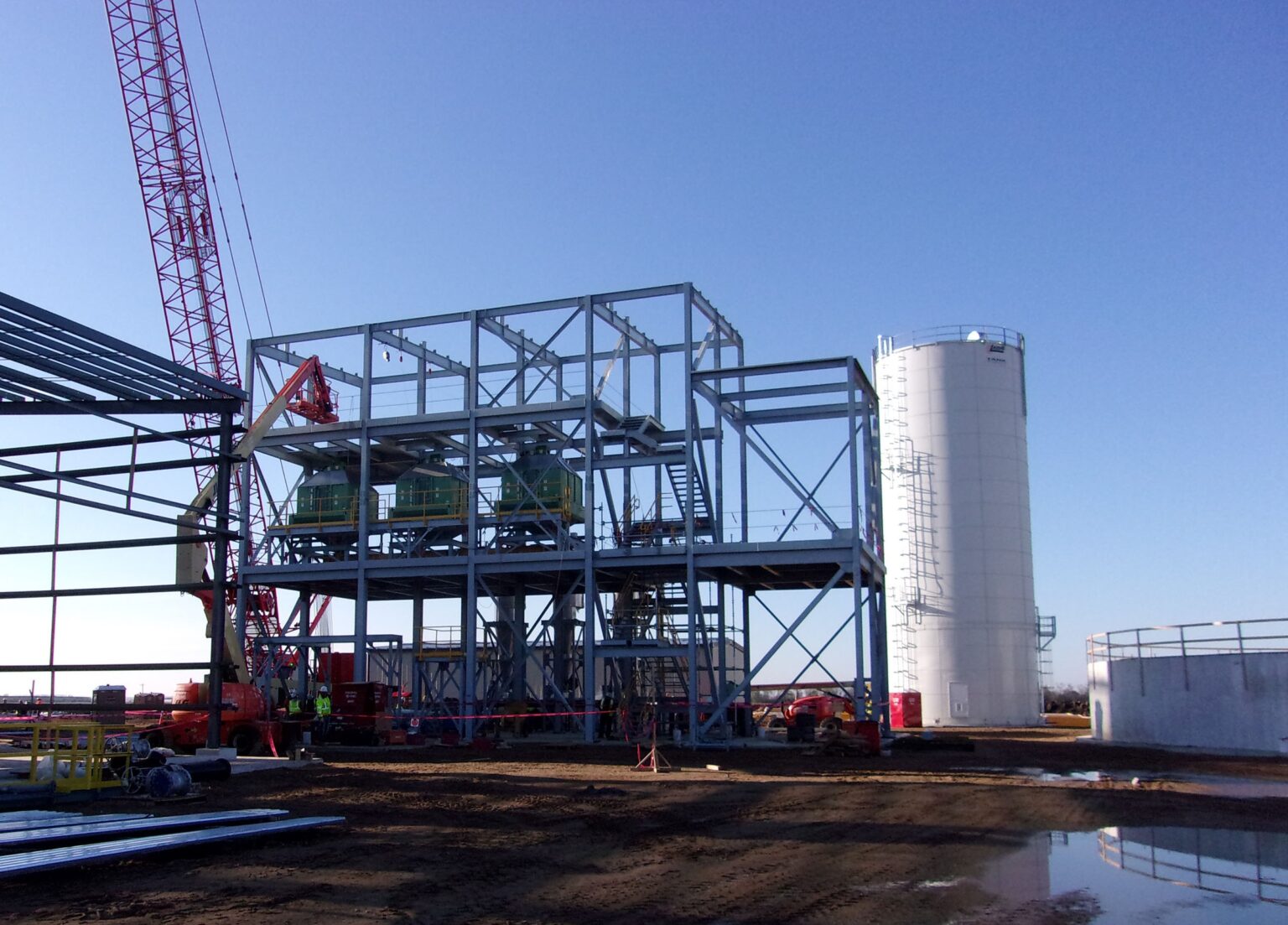

300 TPH Sand Screening Facility

VAA’s multidisciplinary team provided designs and facility layout for the expansion of two facilities, each now capable of producing 25,000 metric tons of sand per year.

Flat Storage Dairy Feed Facility

VAA designed the first dairy mash feed mill in Michigan, resulting in a facility with a 35 ton/hour capacity with extensive safety features.

Koch Foods Replacement Feed Mill

VAA served as the primary design consultant on a new poultry feed mill, using 3D models for layout and design. The resulting mill is capable of producing over 15,000 tons of pelleted feed per week.

Great Western Malting Facility Expansion

VAA designed critical components, overcoming a challenging footprint, to help increase processing capacity by 120 percent.

8-Level Grain Cleaning Expansion

VAA provided comprehensive planning and design within an aggressive 18-month timeframe.

Crystal Valley Co-op Shuttle Train Facility

VAA designed a shuttle train facility capable of handling 3.8 million bushels of corn or soybeans with a loadout capacity of 80,000 bushels/hour.

Summit Brewing Company Facility Expansion

VAA was selected to expand the headquarters of Summit Brewing to facilitate their entry into the canning market. The project had three phases including building expansion, new pipelines, and extensive remodeling.

Fromm Family Foods Pet Food Expansion

VAA provided design services which allowed Fromm Family Foods to reduce truck receiving time by more than half while adding nearly four million pounds of storage to the facility, all while maintaining plant operations.

Canola Crush Processing Facility — Rail Emphasis

VAA’ s multidiscipline team designed a facility capable of producing 850,000 metric tons of canola per year, including a challenging rail design that enabled trains to enter the facility at high speeds while minimizing residential highway blockage.

1,250 Tons/Hour Protein Enhancement Facility

VAA’s multidisciplinary team designed a first-of-its-kind animal nutrition production facility capable of loading out 1,250 tons of final product per hour. Project included the design of complex structures capable of housing substantial equipment loads as well as a compact conveying system designed as a cost saving measure.

3,800 TPD Soybean Processing Plant

VAA’s multidisciplinary engineering team produced 2,294 construction and fabrication drawings used to create a 3,800 TPD soybean processing facility on a 435-acre site capable of processing more than 40 million bushels/year.

The Boathouse®

Meticulous design for a very complex 18,000 SF, 400-seat eatery. The structure includes a 38-foot clear story portion, a two-story portion, a 70-foot tower element, a dock bar and boardwalk areas.

Crude Oil Transload Facility

Designed a facility that includes two 120,000-barrel crude oil storage tanks, a truck receiving area, rail loading, LACT system, and pumping capabilities. The plan included strategically allocated space for a future on-site refinery.

TEMCO Ship Loading Rain Shield

VAA was brought in to determine a viable solution to remedy a substantial ship loading disruption due to rainfall each year. We designed a cantilevered roof nearly 9/10 of an acre in size that could be supported by current dock structures.

Let’s connect.

Interested in learning more? Looking for a specific area of expertise?